Featured Categories

What We're Known For

Featured Products

Check These Out

-

Standard Price: $339.95TEMCo Direct: $305.96

-

TEMCo TH4002 PVC Conduit Heat Blanket Bender 2-3"

Standard Price: $269.95TEMCo Direct: $242.96 -

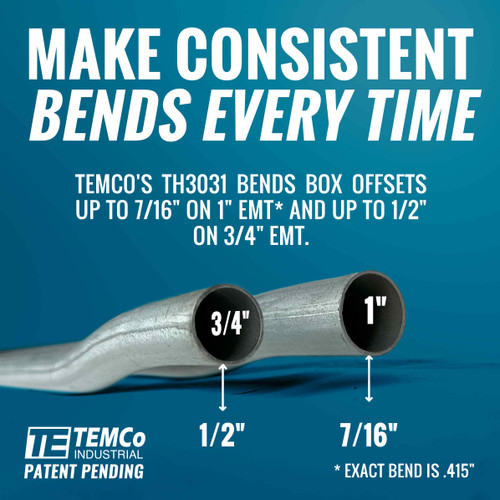

TEMCo Industrial TH3031 1" & 3/4" Conduit Offset Bender

Standard Price: $249.95TEMCo Direct: $224.95 -

TEMCo TH4001 Conduit Heat Blanket Bender 1/2" - 1 1/2" PVC

Standard Price: $159.95TEMCo Direct: $143.96 -

TH0410 TEMCo Rotary Cable Stripper Kit for THHN/XHHW 6 Gauge to 750 MCM (Compatible with any drill)

Standard Price: $189.95TEMCo Direct: $170.95 -

TEMCo TH0415 32-Pair Die Set for the TH0005 Hydraulic Cable Lug Crimper (Work with TH0400 Crimper)

Standard Price: $99.95TEMCo Direct: $89.96 -

TH1818 Hydraulic Dieliess Lug Crimper Tool 10AWG to 400MCM

Standard Price: $89.95TEMCo Direct: $80.95 -

Manual Lever Sheet Metal Stud Punch

Standard Price: $169.95TEMCo Direct: $152.95 -

TH3030 Offset Conduit Bender ½“& ¾” EMT Conduit Bender

Standard Price: $249.95TEMCo Direct: $224.95 -

TH0005 V2.0 Hydraulic Cable Lug Crimper (11 US TON) 10 AWG to 600 MCM Electrical Terminal Cable Wire Tool Kit with 32 Die Sets

Standard Price: $174.95TEMCo Direct: $157.45

New Products

Check out our newest offers!

-

Replacement Case for Original TEMCo TH0037 Hydraulic Knockout Punch Driver

Standard Price: $71.08TEMCo Direct: $51.23 -

Seal Kit for TEMCo Hydraulic Cylinders HC0006, HC0007, HC0008

Standard Price: $14.99TEMCo Direct: $13.49 -

Seal Kit for TEMCo Hydraulic Cylinders HC0005

Standard Price: $19.99TEMCo Direct: $17.99 -

Seal Kit for TEMCo Hydraulic Cylinders HC0002, HC0003

Standard Price: $14.99TEMCo Direct: $13.49 -

TEMCo TH4003 PVC Conduit Heat Blanket Bender 3 1/2"-4"

Standard Price: $339.95TEMCo Direct: $305.96